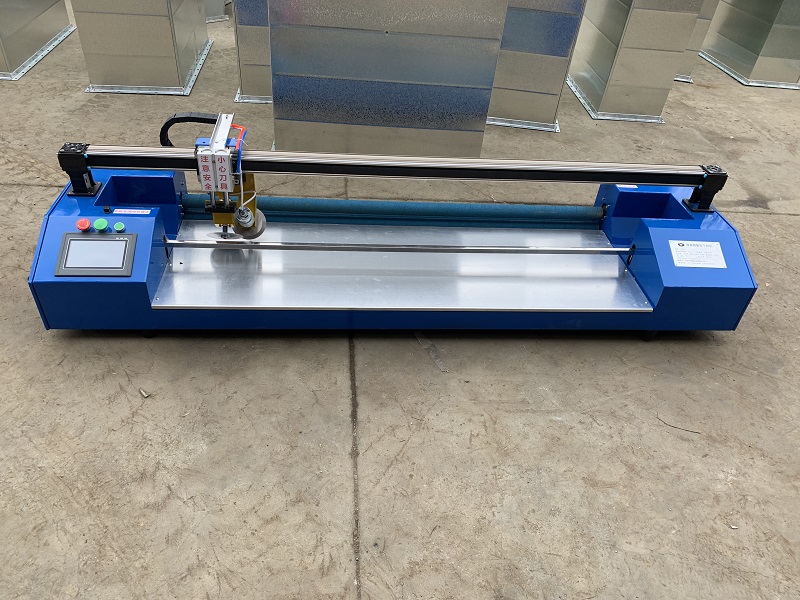

CNC Rubber/Plastic Cotton Blanking Machine

Product Introduction

Introduction of CNC Insulation Cotton Blanking Machine

1、 Overview:

The conventional thermal insulation of galvanized steel air duct is wrapped in four pieces, with many seams and easy to crack, which affects the thermal insulation effect and appearance. The insulation quality is greatly affected by manpower, so that the energy consumption of air conditioning unit is high, the operation cost is large, and the carbon emission is large. The machine solves the above problems effectively by improving the blanking method of insulation plate.

2、 Process:

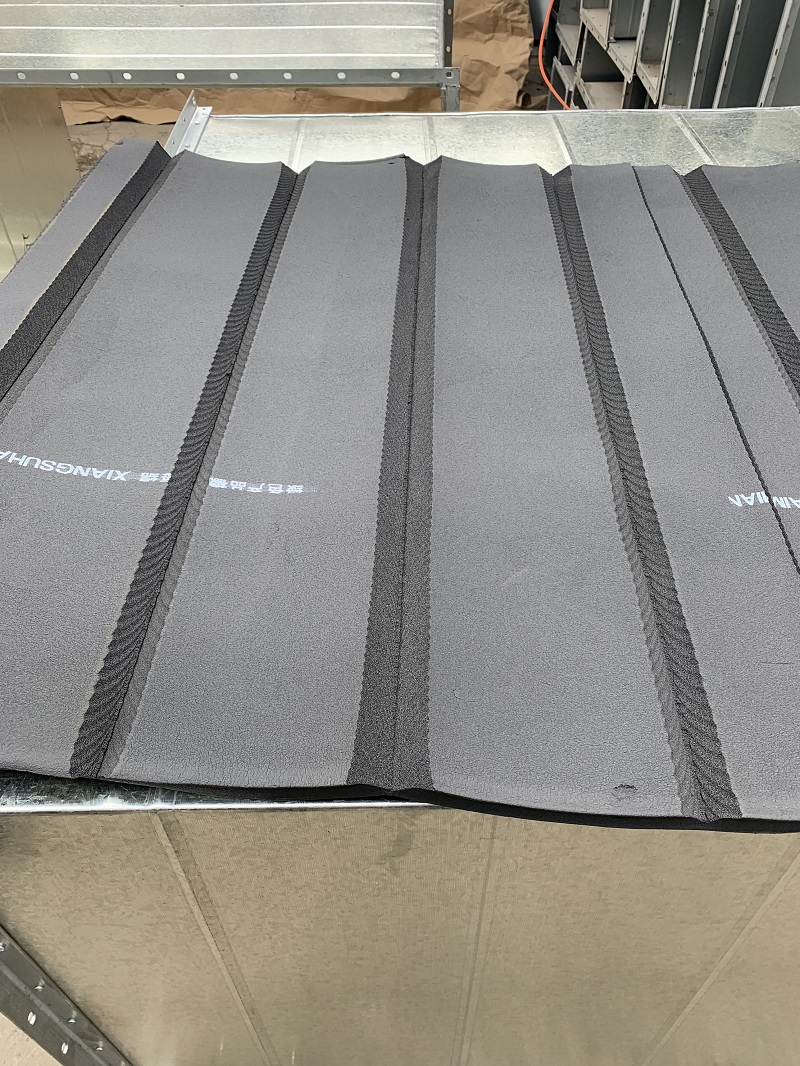

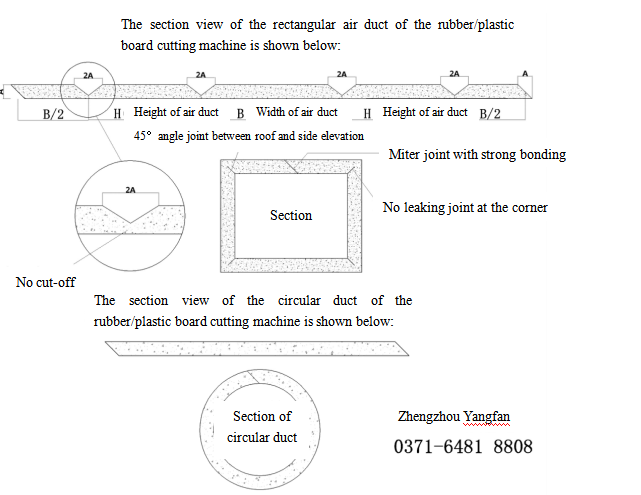

(1). Input two sizes of rectangular duct, insulation cotton plate thickness and quantity when blanking the rectangular duct insulation cotton, and the automatic blanking machine will operate automatically. The machine will open V-groove at the corner of the air duct wrapped with insulation cotton, and leave 3-5mm-thick insulation plate at the bottom of the V-groove, which is not cut through. The cut-off position of each piece of material shall be kept in the middle of the top surface of the air duct, and the cut-off position shall adopt the oblique cut seam.

(2). When rubber & plastic cotton are used for heat preservation, spray environmental protection glue on the air duct and rubber & plastic board respectively. When heat preservation is carried out, the angle of the heat preservation cotton slot will be turned into a right angle, and the air duct shall be kept flat and straight. The top surface joint of the insulation cotton will be pasted with oblique cut joint to increase the pasted area and avoid cracking.

(3). When the glass fiber cotton is used for heat preservation, the glass fiber shall be wrapped first, and then the heat preservation nails shall be welded with the heat preservation nail welder to fix the heat preservation cotton, so as to be more firm and fast. Compared with the traditional procedure of sticking nails first and then heat preservation, it can be completed at one time, and the corner splicing does not need to stick aluminum foil tape again, saving materials and labor.

(4). Input the outer diameter of the round pipe and the thickness and quantity of the rubber & plastic plate directly when cutting the rubber & plastic plate for round pipe. The cutting machine automatically unfolds the cutting and the cutting is inclined, so as to increase the pasted area and ensure the pasting effect.

(5). Significant economic benefits

a. Using CNC blanking machine can blanking 1000m2 insulation cotton per shift, greatly saving labor and high blanking accuracy.

b. The standard section construction is adopted to reduce the construction cost. (it is recommended to customize 1100mm wide rolled rubber & plastic cotton for TDF air duct and 1200mm wide rolled rubber & plastic insulation cotton for angle steel flange air duct).

Main parameters and configuration

|

Serial No. |

Cutting size |

Machine size & Specification |

Remarks |

|

1 |

1.25m width |

Lengh1850mm,Width650mm,Height500mm,

Weight75kgs |

220V,Compressed air supply required |

|

2 |

1.5m width |

Lengh2300mm,Width650mm,Height500mm,

Weight98kgs |

220V,Compressed air supply required |

简体中文

简体中文 English

English